HOW LONG DOES IT REALLY TAKE TO COMMISSION A ROBOTIC CELL?

When discussing automation, one question inevitably arises: “How long will the line be down?” This is not a matter of technical curiosity—it’s a reflection of

High-Impact Applications That Work Perfectly with Refurbished Robots

The Global Trend Toward Accessible Automation The industry is undergoing an interesting shift: many companies are automating processes using refurbished industrial robots because they deliver

CAN ROBOTIC SOLUTIONS WITH REFURBISHED ROBOTS BE ADAPTED TO EXISTING SYSTEMS IN AN INDUSTRIAL WELDING PLANT?

In many plants, welding doesn’t start from scratch: there are already tables, positioners, welding power sources, tooling, extraction systems and, in some cases, software or

UPDATE AND MODERNISATION OF INDUSTRIAL ROBOTS: WHEN IS IT BETTER TO REFURBISH RATHER THAN BUY NEW?

In many workshops, the dilemma arises over whether to purchase a new robot or upgrade the one already installed. Thanks to advancements in controllers, sensors,

REAL CASES IN LATIN AMERICA: HOW SMES CUT COSTS WITH REFURBISHED ROBOTS

For years, industrial automation seemed to be the exclusive realm of large conglomerates. However, the market for refurbished robots is changing that, especially in Latin

ARTIFICIAL INTELLIGENCE APPLIED TO REFURBISHED ROBOTS: EXTENDING THEIR USEFUL LIFE WITH PREDICTIVE MAINTENANCE

For decades, industrial maintenance relied on two straightforward principles: repair when something fails or perform scheduled inspections. Today, Artificial Intelligence is transforming this paradigm. Thanks to real-time data analysis, robots can anticipate failures before they occur, optimise their performance, and extend their operational lifespan. What’s more, this technology isn’t limited to new robots: it can also be applied to refurbished industrial robots, combining sustainability with operational intelligence.

Predictive maintenance powered by AI is based on gathering sensor data—such as vibration, temperature, electrical consumption, and motor torque—and analysing it with algorithms that detect anomalous patterns. If a shaft overheats or a gearbox vibrates slightly outside its normal range, the system issues an alert before the issue causes a breakdown. This enables interventions to be planned at the ideal time, reducing costs and avoiding unexpected downtime.

Leading manufacturers like ABB, KUKA, FANUC, and Yaskawa have developed platforms compatible even with refurbished robots equipped with modern controllers. For instance, a refurbished ABB robot with an IRC5 system can connect to the ABB Ability™ cloud platform for remote monitoring and mechanical health analytics. KUKA provides solutions compatible with KUKA Connect, enabling performance data logging and automatic maintenance scheduling. Even FANUC and Yaskawa offer APIs that, when paired with additional sensors, transform refurbished robots into intelligent units capable of generating predictive reports.

Integrating AI into refurbished robots doesn’t just extend their lifespan; it also maximises return on investment. By detecting faults early, costly repairs are minimised and production stoppages—which can cost thousands of euros per hour—are avoided. Furthermore, the accumulated data enables engineers to improve trajectory programming, optimise energy use, and compare performance between different cells.

A real-world example comes from an automotive plant in Italy, where three refurbished KUKA KR 60 robots fitted with vibration sensors and a local AI system detected micro-wear in gearboxes within six months, preventing a complete line stoppage. In another case, a Polish electronics factory using a refurbished ABB IRB 4600 with predictive diagnostics software reduced maintenance times by 25% and extended its expected operational cycle by over two years.

These experiences show that refurbished robots can not only match but even surpass the efficiency of new ones when combined with artificial intelligence and advanced monitoring. The key lies in integration: strategically placed sensors, secure connectivity, and continuous analysis.

From a sustainability perspective, this evolution also has a positive environmental impact. Extending a robot’s lifespan by five years means avoiding the production of a new one, saving thousands of kilos in materials and energy. Properly applied AI makes refurbished robotics a model for the digital circular economy: reused technology with an updated brain.

At URC, we integrate predictive maintenance solutions and smart connectivity into refurbished ABB, KUKA, FANUC, and Yaskawa robots, ensuring precision, reliability, and long service life. We combine engineering and data so each robot works more intelligently, efficiently, and sustainably.

THE ECONOMICS OF USED ROBOTS: UNDERSTANDING THE TRUE TOTAL COST OF OWNERSHIP (TCO) VERSUS A NEW ROBOT

Buying a robot is not simply a technical decision. In reality, it is a financial one. Many companies believe that the most expensive robot is the best, or that it is safer to buy new to “avoid risks”. However, when analysed from a business perspective, with numbers and strategy, the reality is quite different: what matters is not the purchase price, but the total cost of ownership (TCO). And from this point of view, a refurbished industrial robot is not only competitive—it is, in many cases, the smartest choice.

The TCO is the actual cost of owning a robot over its entire useful life. It includes not just the purchase price, but also installation, spare parts, maintenance, energy consumption, unplanned downtime, training, integration, and remaining useful life. Many companies are surprised to discover that a refurbished robot can have a TCO up to 50% lower than a new one, with the same productive performance.

Why does this happen? Firstly, because a new robot includes an upfront premium related to brand, marketing, and technological depreciation. A new ABB IRB 4600 or KUKA KR 60 can cost two or even three times more than their certified refurbished versions, even though operationally, the practical difference is minimal for typical industrial tasks such as welding, palletising, machining, handling, or inspection.

Moreover, a certified refurbished robot has already overcome its initial failure curve. In other words, it has already “proven” its mechanical and electrical stability in production. During refurbishment, gearboxes are adjusted, cables and seals are replaced, lubrication is renewed, motors are tested, and axes are precisely calibrated. The result? With proper preventive maintenance, it can continue working reliably for another 8 to 12 years.

Then there is the cost of time. Many factories lose money due to automation delays. A new robot may take months to be delivered, especially during periods of high global demand. Refurbished robots, on the other hand, are available immediately. Being able to start an automation project four months earlier has a real financial impact, as it accelerates return on investment and reduces dependence on scarce labour.

There is also a factor few companies consider: refurbished robots allow for progressive scalability. Instead of buying five new robots and restructuring the entire line, a smart plant can start with just one refurbished FANUC M-20iA or Yaskawa GP12, automate a critical operation, quickly recover the investment, and reinvest. This approach reduces financial risk and lets you refine the project step by step, without blind bets or unnecessary debt.

TCO also depends on the ecosystem. A new robot often requires new spare parts, mandatory support contracts, and sometimes more expensive proprietary software. By contrast, refurbished industrial robots have a global market for spare parts, are compatible with standard accessories (grippers, rotary tables, sensors), and many allow integration with Siemens, Rockwell, or Beckhoff PLCs without barriers.

In summary, when a plant manager, financial director or business owner truly evaluates the investment, the question is no longer: “New or used?”, but rather: “Which option gives me more productivity per euro invested?” And by that metric, the certified refurbished robot wins.

Because it is not about spending more, but about investing better.

At URC, we help companies of all sizes reduce their TCO through smart automation with refurbished ABB, KUKA, FANUC, and Yaskawa robots. Each robot is delivered tested, certified, and ready for production. We speak the language of factories: productivity, reliability, and return on investment.

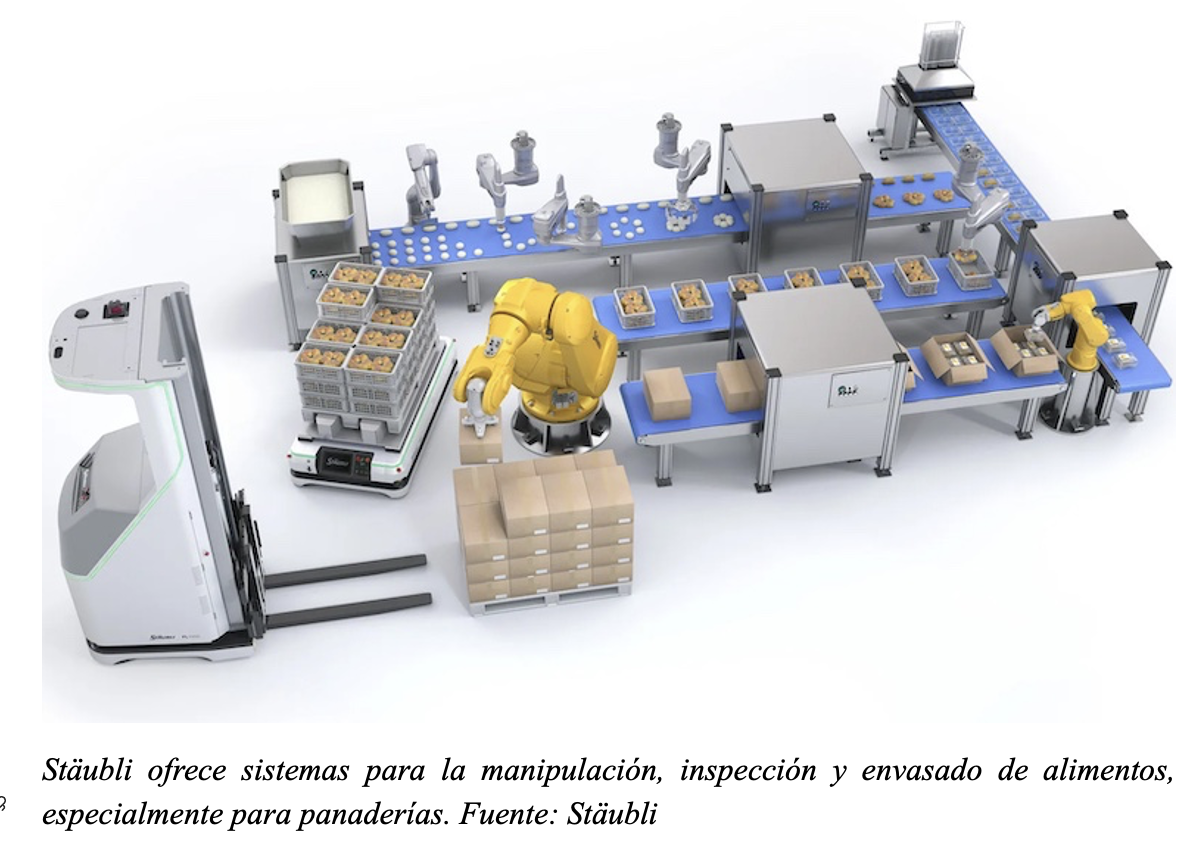

BEYOND THE OVEN: ROBOTICS REVOLUTIONISES INSPECTION AND HANDLING IN BAKERIES

In today’s increasingly competitive industrial landscape, gantry robots—also known as Cartesian robots—are emerging as one of the most versatile and efficient solutions for automation. Unlike articulated or SCARA robots, gantry systems are mounted on elevated structures that move across the workspace. This configuration allows them to handle parts with high precision, cover large surface areas, and free up valuable floor space.

These robots are widely used across various industries for material handling, pick-and-place operations, assembly, dispensing, sealing, and welding tasks within production lines. Their elevated positioning makes them especially suitable for sectors such as automotive, where they manage heavy components, feed welding stations, or transfer parts between lines; aerospace, where they handle large-scale components requiring accuracy and repeatability; consumer goods, where they streamline packaging, palletizing, and order preparation; and smart logistics, where they efficiently sort and move goods in tight spaces.

One of the key advantages of gantry robots lies in their ability to optimize space. Operating from above, they eliminate the need for floor-mounted equipment, which is crucial in facilities with physical constraints. Their adaptability is another strength—they can be equipped with a wide range of end effectors, such as grippers, welders, or suction cups, to suit different applications. In terms of performance, they help reduce cycle times, minimize human error, and boost overall line productivity. Their elevated reach also enables access to areas that ground-mounted robots simply cannot cover.

While articulated robots dominate the market for their flexible movement and SCARA robots excel in high-speed repetitive tasks, gantry systems stand out in large-scale operations that require long, linear travel. Articulated robots often take up floor space and face limitations in reach, whereas gantry robots offer superior spatial efficiency and coverage across expansive work zones.

Companies like URC, based in Bilbao, bring valuable expertise in supplying refurbished industrial robots and complete cells that integrate peripherals such as linear tracks, positioners, and welding systems. Their facilities often showcase robots moving along linear guides—a concept closely aligned with gantry systems. Moreover, their thorough inspection of axes, wrists, and calibration ensures the precision required for applications where linear motion is critical.

This level of know-how in advanced automation and robotic cells demonstrates how gantry systems, when paired with high-quality refurbished robots, can become an accessible and strategic solution for companies aiming to maximize space, reduce cycle times, and enhance productivity without compromising on accuracy.

INTEGRATION OF YASKAWA MOTOMAN ROBOTIC WELDERS: PRECISION AND EFFICIENCY IN MANUFACTURING

Welding is one of the most critical and demanding processes in the manufacturing industry. Precision, repeatability, and safety are essential to ensure the quality of the final product. Yaskawa Motoman, known for its expertise in welding automation, has developed robots and integrated solutions that optimize this process, lowering costs and boosting productivity.

Yaskawa Motoman’s welding robots, such as the AR1440 and AR3120, are designed to deliver high-quality arc welding in automotive, metalworking, and heavy machinery applications. These models offer extended reach and payload capacity, making them ideal for large or complex parts. Their advanced path control systems ensure consistent, high-quality weld seams, while integration with vision systems allows for precise adjustments and millimeter-level accuracy. They are also compatible with leading welding power sources like Fronius, Lincoln Electric, and Miller.

One of Yaskawa’s most powerful tools is the YRC1000 controller, which enables intuitive programming and monitoring of the welding process, as well as coordination of multiple robots for simultaneous operations.

In a trailer manufacturing plant in Mexico, two Yaskawa AR3120 robots were deployed for chassis welding. The setup included vision systems and rotary positioners to handle the parts. The results were impressive: welding time was reduced by 40%, rework due to weld defects was nearly eliminated, and production capacity increased by 30%—all without adding more personnel.

Compared to manual welding, robotic welding offers several advantages: 24/7 operation without fatigue, consistent welds every time, reduced exposure of workers to fumes and radiation, and less waste of materials and consumables.

Integrating Yaskawa Motoman welding robots is a strategic move for companies seeking consistent quality, faster production, and lower operational costs. Their precision and ability to work in sync within complex industrial environments make them a highly efficient solution in the field of industrial welding.

FROM THE FACTORY TO THE SMART ECOSYSTEM: THE RISE OF ROBOTIC SWARMS

Swarm robotics, inspired by the behavior of social insects, is no longer just a laboratory concept—it’s becoming a practical solution in industries such as logistics, construction, and advanced manufacturing. This approach enables multiple robots to work together in a decentralized manner, tackling tasks that once required complex centralized systems.

The Essence of Swarm Robotics

Unlike traditional automation systems, where each robot is controlled by a central unit, swarm robotics relies on distributed autonomy. Each robot follows simple rules, but collectively they generate intelligent, adaptive behavior that responds in real time to changing conditions. This makes swarm robotics ideal for dynamic environments like warehouses or assembly lines, where constant variation is the norm.

Breakthroughs in Research

One of the most notable recent developments is RoboBallet, a project led by University College London (UCL) in collaboration with Google DeepMind. It coordinates up to eight robotic arms to perform 40 tasks within seconds. Using AI algorithms, the system prevents collisions and optimizes group movements—marking a milestone in multi-robot planning.

Other programs, such as Centibots and Symbrion, have long demonstrated that simple robots can self-organize to explore spaces, transport objects, or even assemble into cooperative structures. Backed by research institutions in the U.S. and Europe, these initiatives laid the groundwork for today’s industrial swarm robotics.

Emerging Industrial Applications

The automotive industry is among the first to embrace this paradigm. Companies like Arrival have documented assembly processes where groups of robots simultaneously build electric vehicles—eliminating the need for a static production line. This approach offers greater flexibility, lower costs, and adaptability for small or customized production runs.

In logistics, large warehouses are experimenting with fleets of mobile robots that self-organize to move goods more efficiently than traditional systems. The key lies in their independence: each robot makes local decisions that, together, result in a coordinated and seamless operation.

Swarm robotics is reshaping the landscape of industrial automation. What began as an experimental concept inspired by insect behavior has evolved into a practical model that enhances resilience, flexibility, and efficiency in factories and logistics centers.

Advances in AI, inter-robot communication, and distributed planning are driving adoption in strategic sectors like automotive and logistics. In the coming years, we’ll witness mass production shift toward dynamic networks of collaborative robots—capable of operating as a self-sufficient, adaptive swarm.

YASKAWA AND MULTIVAC: PACKAGING INNOVATION WITH RX 4.0 THERMOFORMER AND SIX-AXIS ROBOT

In the fast-moving world of industrial automation, the collaboration between Yaskawa and MULTIVAC marks a significant milestone. The integration of Yaskawa’s six-axis MOTOMAN HD7 robot into MULTIVAC’s RX 4.0 thermoforming machine sets new standards in the medical and pharmaceutical industries, fully aligning with stringent Good Manufacturing Practice (GMP) regulations.

A New Era in Packaging Innovation

The RX 4.0 thermoformer by MULTIVAC was designed to meet rising demands for precision and consistency in packaging sensitive products across healthcare sectors. More than just reducing production times, the system enhances operational efficiency and adaptability. A standout feature is the first-ever incorporation of a six-axis Yaskawa robot at the end of the production line, bringing unprecedented flexibility to the packaging process.

MOTOMAN HD7: Precision Meets Versatility

Chosen after a rigorous market analysis, the MOTOMAN HD7 stands out for its cleanroom compatibility and full GMP compliance. Developed in collaboration with the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA), this robot is suitable for environments ranging from ISO Class 5 to GMP Class A — the highest hygiene standard.

Its six-axis structure allows both single and multi-point loading and unloading operations. In demo setups, it’s been equipped with a five-point vacuum head for handling packages, which can be placed onto moving conveyor belts or at fixed, designated positions. The HD7’s range of motion enables it to access various positions without constraint, offering remarkable format flexibility.

Seamless Integration and Smart Control

The robot’s integration into the RX 4.0 platform is made possible through Yaskawa’s MotoLogix software interface, which embeds robotic kinematics directly into MULTIVAC’s control system and programming environment. This ensures centralized line operation from a single platform, boosting efficiency and streamlining system complexity.

The partnership between Yaskawa and MULTIVAC in deploying the MOTOMAN HD7 represents a significant leap forward in packaging automation for the medical and pharmaceutical industries. Not only does it enhance process precision and flexibility, but it also sets a new benchmark in GMP compliance—ensuring consistently high product quality and safety.

THE DIGITAL REVOLUTION IN FEED MANUFACTURING: THE PROGANDO SUCCESS STORY WITH ARBENTIA AND MICROSOFT

In the era of Industry 4.0—where connectivity and automation are reshaping every industry—digitalizing processes has become essential for staying competitive. A clear example of this transformation is Progando, a leading Galician company in animal nutrition, which has achieved a major milestone by integrating its feed manufacturing and sales operations through a strategic collaboration with ARBENTIA and Microsoft. This project not only streamlines management but also lays the foundation for a smarter, more responsive value chain.

Rooted in the Provincial Agricultural Cooperative of A Coruña (Leyma) and deeply committed to rural development, Progando faced the challenge of unifying and monitoring its complex feed production and distribution processes, along with managing its ProSardín retail stores. The solution came with Microsoft Dynamics 365 Business Central, a cloud-based ERP system that enabled Progando to consolidate all its operations into a single database.

Led by ARBENTIA, the implementation resulted in full integration of workflows—from purchasing and finance to logistics and production. This advanced digitalization allows real-time monitoring of both the factory and the stores, ensuring tight inventory control, batch traceability, and compliance with food safety and quality regulations. Integration with tools like Microsoft Power BI has further empowered Progando with robust analytics capabilities, enabling faster, data-driven decision-making.

“We aimed to integrate all our workflows and make better decisions using tools like Microsoft Power BI,” explains Adrián Veras from Progando, highlighting how technology has elevated the value of their work and allowed the team to focus on higher-value tasks.

Progando is a family-run Galician company and a benchmark in the animal nutrition and agricultural distribution sector. Operating within the Leyma cooperative, its mission is to support farmers and develop cutting-edge technologies for agricultural production, promoting efficiency and sustainability in rural areas. In a year of strong growth, the company reported €69.5 million in revenue and reached a record production of 120,000 tons.

ARBENTIA, a digital transformation expert, supports businesses in their technological evolution. Specializing in the development and implementation of intelligent solutions based on Microsoft Dynamics 365, ARBENTIA focuses on improving efficiency, traceability, and profitability across the entire value chain—from production to distribution. It positions itself as a key strategic partner in business modernization, offering specialized software for feed distribution and promoting operational excellence.

Microsoft, the global tech giant, is a leading provider of software, services, and solutions that transform how businesses operate. In this project, its Dynamics 365 Business Central and Power BI platforms form the digital backbone, delivering the cloud infrastructure needed for integrated, flexible, and scalable management. Microsoft’s technology is essential for boosting operational efficiency and enabling powerful data analysis, bringing the vision of Industry 4.0 to life for companies of all sizes and sectors.

This success story underscores how the right combination of strategic vision, advanced technology, and expert implementation can lead to full digital transformation of industrial processes—marking a turning point in the efficiency and competitiveness of the agri-food sector.